The Theory bit (feel free to skip this but it is worth keeping in mind!)

Every IR device worth its salt should allow the user the ability to adjust the emissivity to that of the material being examined – this goes for a spot radiometer as much as it does for an IR camera. Emissivity is a measure of the the ability of the surface you are observing to emit IR radiation, and is the opposite of reflectivity. To make this easier to understand, everything – even an iceberg, emits IR radiation of some sort as long as it is above absolute zero (-273°C). The efficiency with which the surface emits is a factor called Emissivity, and it measures the ratio of the emitted IR energy of the surface when compared to a black body at the same temperature. The numbers are in the range 0 – 1, where 0 is a perfect mirror and 1 is a perfect black body. In the real world every surface has an emissivity value between these points and there are table that can give you measured values. Typically these values are relatively stable, but you should be aware that they can and do change as temperatures change significantly. The values also change depending on the part of the IR spectrum you are using – but as this is device dependent it doesn’t matter a lot if you use the same device or devices in the same IR Band.

The Practical Bit:

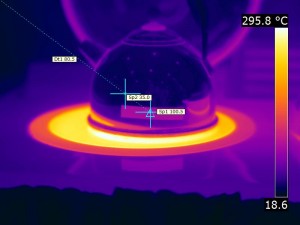

This depends on you having some material whose emissivity you know – for example some electrical insulation tape, or you can buy emissivity targets from a number of sources such as IRISS Infrared. If you don’t have a known material then get some electrical insulation tape, and stick it on the side of your kettle (preferably not a stainless steel one unless that’s all you’ve got), make sure this is below the waterline. Boil the kettle and when it’s boiling, measure the temperature of the tape. If your device does not give 100°C / 212°F then adjust the emissivity in you camera until it does – make a note of this value for this brand of tape, it is useful later. Repeat this on a block of ice – the values should be pretty similar. NOTE: if you are using a stainless steel kettle, and you measure the temperature of the kettle as it boils, you will get a value nowhere near 100°C – the emissivity of stainless steel is very low and you need to adjust to the emissivity of stainless to get the measurement accurately. See the images below as an example

So now you can see the difference in temperature indicated between Spot 1 (100°C ) on the tape with emissivity set to 0.97 and the temp indicated by Spot 2 (35°C) with the same emissivity, but “measured” directly on the Stainless – if you adjust for the emissivity of the stainless (0.14), the Tape temperature will indicate 320°C!

Now when you come to measure the temperature of something and you don’t know the emissivity, stick the tape on the surface, enter the value of the emissivity for the tape and measure the tape’s temperature. This will be very close to that of the surface you are on. Now measure the surface temperature without the tape, and adjust the emissivity in your device until the temperature reads the same – you now have an estimate of the emissivity of the surface. QED

Why is Emissivity Important?

If you want an accurate temperature measurement using IR, you need to use emissivity values – emissivity adjusts for the ability of a surface to emit IR radiation compared to a theoretical black body. As a rule of thumb rough surfaces have higher emissivity than shiny surfaces, and metals are normally low emissivity materials.

What are typical values of Emissivity?

This firstly depends on 2 factors – the IR band your device is operating in (SW, MW or LW) and the temperature it is measured at, however there are tables available for many different materials, some examples of which are:

| Material | Temperature (°C) | emissivity |

| Brick – Red | 20 | 0.90 |

| Masonry – plastered | 20 | 0.94 |

| Concrete | 20 | 0.92 |

| Printed Circuit Board | 70 | 0.91 |

| Stainless Steel (Polished) | 70 | 0.14 |

| Iron and Steel – (Rusted) | 20 | 0.69 |

| Copper (commercial) | 20 | 0.07 |

| Copper (heavily oxidised) | 20 | 0.78 |